Beyond Quality

Going The Distance

At Qi to Life, our quality control begins with Mother Nature. Every year our manufacturing team goes deep into the forest to get the purest wild strain of each mushroom from their native locations (their DaoDi region). Then, following traditional cultivation practices, specimens are sent to the Chinese Academy of Science for DNA testing. Even though this endeavor is both laborsome and time- intensive, we consider it worth the investment. It is the most effective way to preserve the maximum efficiency of the medicinal properties of the mushrooms, guaranteeing you the highest quality extract.

From there, our mushroom extracts are meticulously crafted in an FDA registered, GMP certified facility. The facility adheres to strict international quality standards that are enforced in our state-of-the-art laboratory. Both raw and finished materials undergo rigorous inspection by our in-house quality control unit. Every phase of the extraction process is closely monitored and is in strict accordance with established Standard Operation Procedures. We utilize the traditional method of water and alcohol extraction to maintain the full integrity of our extracts. The water used in cleaning and processing undergoes thorough purification via an ultrafiltration system that maintains purity throughout production.

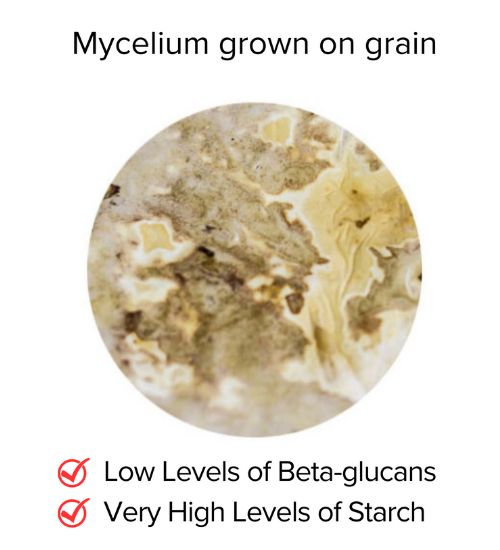

We uphold our commitment to quality by subjecting our mushroom extracts to numerous international standards in testing. We use the Megazyme method to ensure the beta-glucan potency of our extracts. Recognized internationally, by the USDA, and peer-reviewed research, it provides the most reliable measurement for distinguishing beta-glucan and alpha-glucan/starch content in mushrooms. This method identifies not only the potency of beta-glucans but also the presence of fillers like starches and grain in lower-quality mushroom products trying to pass themselves off as better than they are.

Qi to Life’s commitment to this comprehensive approach ensures that our customers receive a medicinal mushroom extract compound of unparalleled quality. Syner’Qi delivers reliable, unadulterated, potent concentrations of Mother Nature’s essential healing elements combined into one functional blend.

Quality Control & Quality Assurance stages include:

- Quality on the farm

- Quality on receiving the raw material

- Microbiological testing

- Organoleptic testing

- Moisture content analysis

- In-house laboratory testing and segregation of raw material

- Ash testing

- pH testing

- Aflatoxin testing

- Heavy metal analysis

- Pesticide analysis

- Bioactive analysis

The Hidden Truth: 90% of Popular Mushroom

Supplement Companies Don’t Contain Real Mushrooms

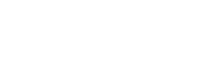

The hidden truth: more than 90% of popular supplement companies that feature mushroom products don’t contain any real mushrooms. The reason lies in the widespread use of mycelium, the root-like structure of the mushroom. The problem is that 90% of the beneficial compounds reside in the non-root part called the fruiting body.

This deceptive practice has even led the FDA to update labeling requirements, urging companies to differentiate between mycelium and fruiting body ingredients. However, many still resort to misleading terms like “mushroom extract” to disguise the use of mycelium.

Unraveling this deception reveals the cost-cutting motive behind choosing mycelium over real mushrooms. Mycelium can be grown in tanks in 3-5 days, irrespective of location or weather conditions, making it a lower-quality choice. In contrast, cultivating genuine mushrooms requires time, space, and specific environmental conditions. The typical growth period of a mushroom can be around 8 months.

For those seeking authentic, powerful healing benefits from medicinal mushrooms – the solution lies in choosing a manufacturer committed to using 100% fully fruiting mushrooms, certified organic practices, traditional growing mediums, and rigorous quality testing. Qi to Life’s Syner’Qi stands as a testament to these principles and not only fulfills these high standards but exceeds them.

Every year our manufacturing team goes deep into the forest to get the purest wild strain of each mushroom from their native locations (their DaoDi region) and sends them in for DNA testing to ensure authenticity. From there, our state-of-the-art facility tests for heavy metals, pesticides/herbicides, molds, other microbals, and employs the Megazyme method to guarantee the beta-glucan potency in our extracts. This ensures the safety, certainty, and effectiveness of our products – no questions asked.